Spray&Aerosol Filling Machine

Sunter Machinery’s spray and aerosol filling machines are widely used in various industries, including home care, personal care, health care, and car care, for filling all kinds of spray and aerosol products. We provide diverse filling solutions for aerosol bottles of different specifications and materials, and can efficiently customize different types of aerosol filling solutions according to customer needs, helping customers significantly reduce production costs, effectively save labor resources, and comprehensively improve your productivity.

Spray&Aerosol

Filling Machine

The aerosol filling production line features high-speed, high-precision filling, and airtight sealing, along with adjustable inflation pressure. This production line is widely applicable for filling various solvents. Its design concept emphasizes production efficiency and operational reliability, flexibly adapting to diverse product specifications, making it an efficient solution for meeting large-scale production demands.

Spray&Aerosol Filling Series

This spry&aerosol filling equipment integrates pneumatic and electrical control, independent filling heads, automatic sealing detection, and guided inflation, achieving precise and efficient operation while minimizing air consumption. It features high-speed, high-precision filling and airtight sealing, with adjustable inflation pressure, and is widely applicable for various solvents. The design emphasizes high efficiency, safety, ease of maintenance, compliance with international standards, flexible adaptation to diverse product specifications, and meeting large-scale production demands.

Automatic Aerosol Filling Production Line

Medical aerosol 20mm valve filling machine

Miniature automatic aerosol filling machine

Spray Bottle Filling Machine

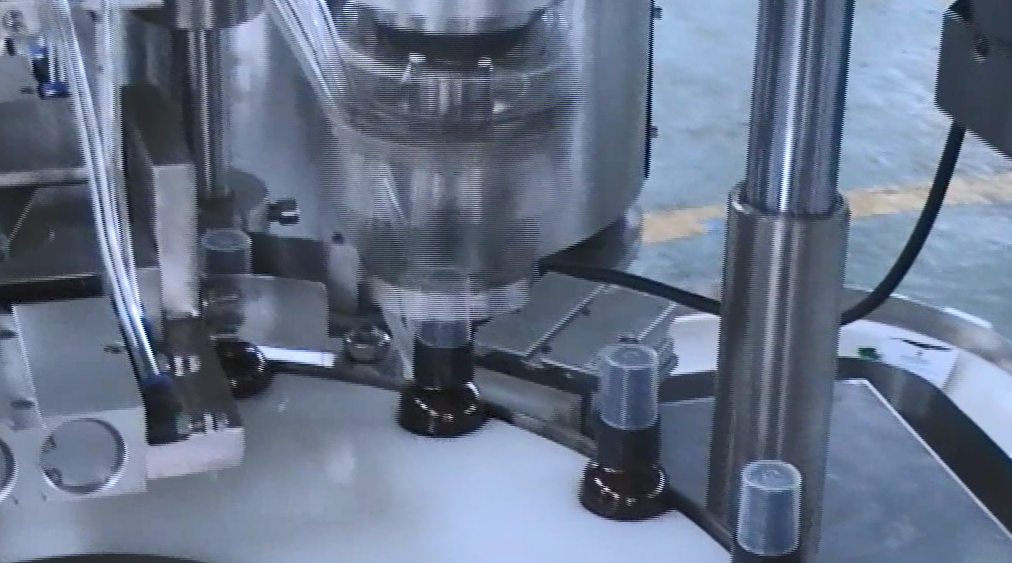

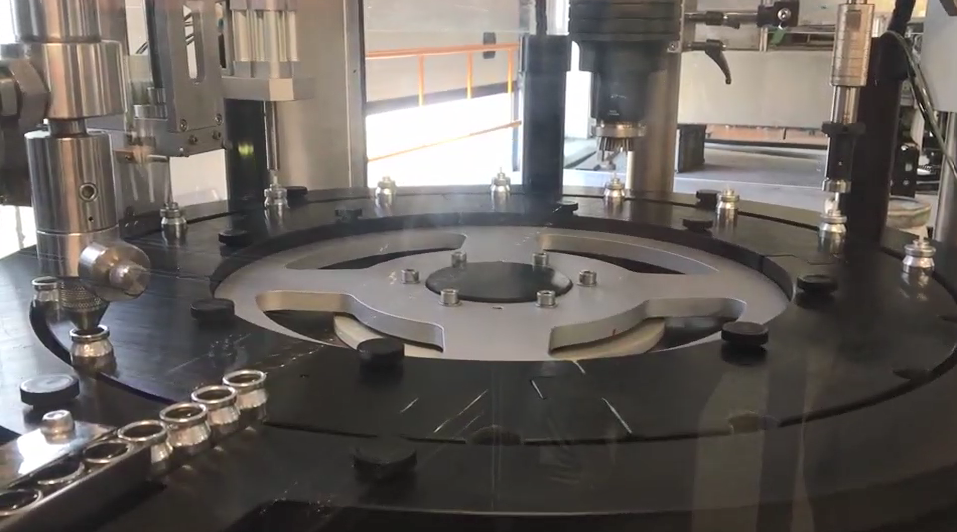

Spray&Aerosol filling machines in action!

Parts details

All spare parts are designed to be fully compatible with specific models of filling machinery, ensuring minimal downtime during replacement. We adhere to international standards such as ISO 9001 and GMP, manufacturing under strict quality control. These spare parts collectively enhance the reliability, efficiency, and precision of filling machinery, making them indispensable for maintaining optimal performance in high-demand production environments.

What well-known brands are used for key components (e.g., electrical components) in the aerosol filling production equipment?

We utilize internationally renowned brands such as Siemens, Schneider, and Panasonic for key components. Additionally, specific brands can be selected based on customer requirements to meet personalized needs.

Can the aerosol filling production equipment be customized to fit our existing production line?

Yes, the equipment can be custom-designed to align with the specific requirements of your existing production line, ensuring seamless integration and efficient operation.

How does the aerosol filling production equipment ensure hygienic safety during the filling process?

The equipment is constructed from high-quality stainless steel and complies with GMP (Good Manufacturing Practice) standards, effectively preventing contamination. Furthermore, the filling system is designed for easy cleaning and sterilization, ensuring hygienic safety during production and meeting the stringent standards of industries such as pharmaceuticals and cosmetics.

Does the aerosol filling production equipment require additional adjustments to fill products with different dosages?

No complex adjustments are necessary. The equipment is equipped with high-precision metering pumps and a flexible control system, allowing dosage parameters to be easily adjusted via PLC or touchscreen to accommodate various product specifications.

What is the production capacity of the aerosol filling production equipment, and can it meet large-scale order demands?

The equipment features a high level of automation and optimized production efficiency, with specific capacity varying by model and configuration. Generally, it is capable of reliably supporting large-scale order demands. For detailed capacity assessments, please contact us with your specific requirements.

What is the repair process if the equipment malfunctions?

Within the one-year warranty period, we provide comprehensive repair support. In the event of a malfunction, you may contact our technical team, and we will first attempt to resolve the issue through remote diagnostics. If on-site repair is required, we will arrange for professional technicians to assist, ensuring the equipment is restored to normal operation as quickly as possible.

What types of propellants does the aerosol filling production equipment support?

The equipment is compatible with commonly used propellants, including compressed gases (e.g., nitrogen, carbon dioxide) and liquefied gases (e.g., propane, butane). Compatibility can be customized based on your product requirements; please provide detailed specifications for further confirmation.

Ready to Boost Your Productivity?

Contact us today to discuss your specific filling line requirements and discover how Sunter Machinery can help optimize your production process.

Contact Form

Fill out the form below and we will get back to you shortly.