Chemical Liquids Filling Machine

Sunter Machinery’s spray and aerosol filling machines are widely used in various industries, including home care, personal care, health care, and car care, for filling all kinds of spray and aerosol products. We provide diverse filling solutions for aerosol bottles of different specifications and materials, and can efficiently customize different types of aerosol filling solutions according to customer needs, helping customers significantly reduce production costs, effectively save labor resources, and comprehensively improve your productivity.

Please Choose your need

E-liquid Filling Machine

The aerosol filling production line features high-speed, high-precision filling, and airtight sealing, along with adjustable inflation pressure. This production line is widely applicable for filling various solvents. Its design concept emphasizes production efficiency and operational reliability, flexibly adapting to diverse product specifications, making it an efficient solution for meeting large-scale production demands.

E-liquid Filling Series

Sunter Machinery can customise chili sauce filling solutions to suit your chili sauce bottle size and filling capacity.Such as semi-automatic chilli sauce filling machine, piston chilli sauce filling machine, paste filling machine (with stirring and heating), weighing chilli sauce filling machine, self-flowing chilli sauce filling machine and so on.

10ML Liquid Filling Machine

30-100ML E-liquid Filling Production Line

Automatic E-liquid Filling Production Line

E-juice Bottle Filling Machine

100ML E-liquid Filling Production Line

Glass E-liquid Bottle Filling Machine

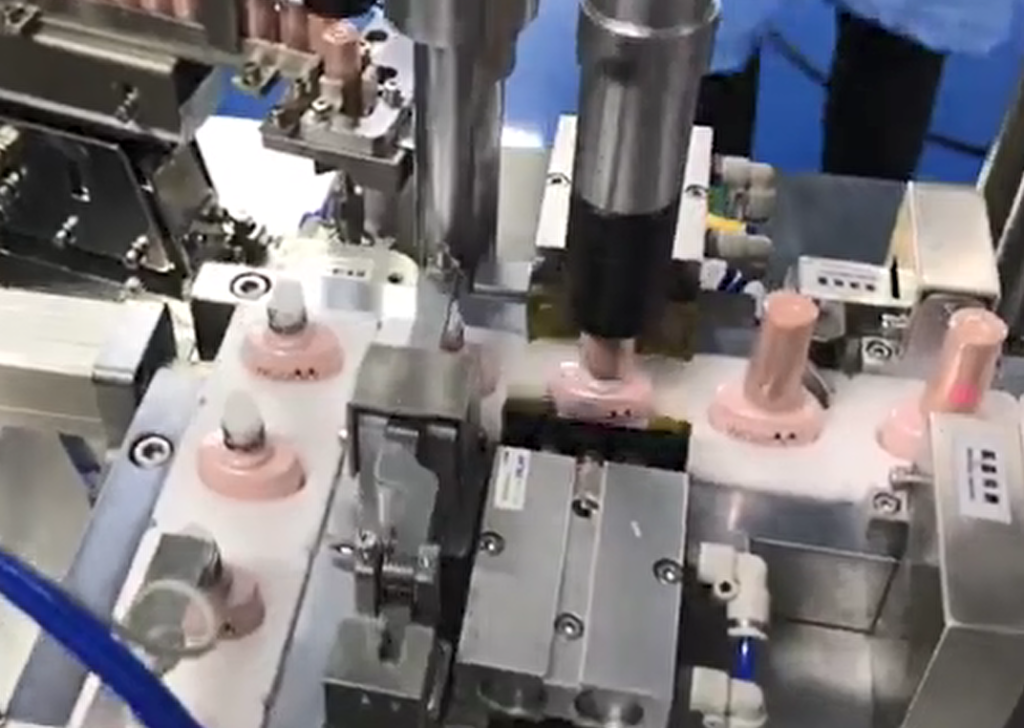

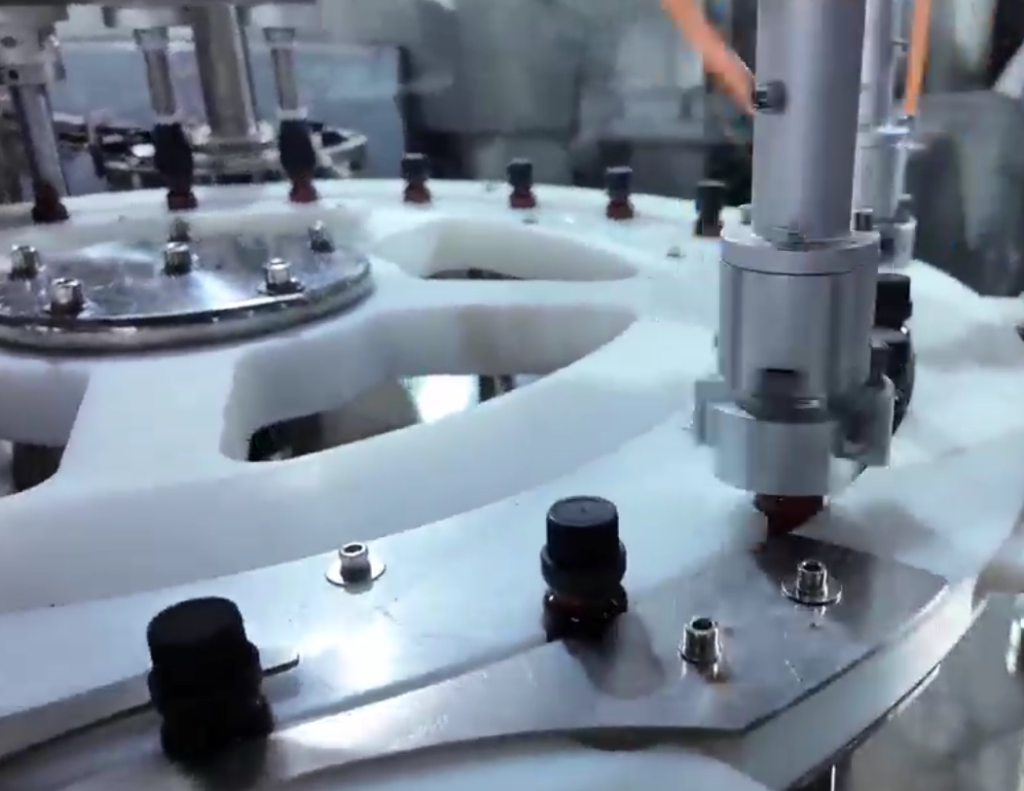

E-liquid filling machines in action!

Nail Polish Filling Machine

The aerosol filling production line features high-speed, high-precision filling, and airtight sealing, along with adjustable inflation pressure. This production line is widely applicable for filling various solvents. Its design concept emphasizes production efficiency and operational reliability, flexibly adapting to diverse product specifications, making it an efficient solution for meeting large-scale production demands.

Nail Polish Filling Series

This ketchup / tomato sauce filling machine is mainly suitable for filling and capping semi-liquid products without or with small particles. The tomato sauce filling machine can be customized with 4/6/8/12/14/etc filling heads according to customer’s production capacity.

Automatic Nail Polish Filling Machine

Nail Polish filling machines in action!

Glue Filling Machine

The aerosol filling production line features high-speed, high-precision filling, and airtight sealing, along with adjustable inflation pressure. This production line is widely applicable for filling various solvents. Its design concept emphasizes production efficiency and operational reliability, flexibly adapting to diverse product specifications, making it an efficient solution for meeting large-scale production demands.

Glue Filling Series

This ketchup / tomato sauce filling machine is mainly suitable for filling and capping semi-liquid products without or with small particles. The tomato sauce filling machine can be customized with 4/6/8/12/14/etc filling heads according to customer’s production capacity.

Automatic 10-200ml Glue Filling Machine

Automatic 1-5L Glue Filling Machine

Glue filling machines in action!

Glass Water

Filling Machine

The aerosol filling production line features high-speed, high-precision filling, and airtight sealing, along with adjustable inflation pressure. This production line is widely applicable for filling various solvents. Its design concept emphasizes production efficiency and operational reliability, flexibly adapting to diverse product specifications, making it an efficient solution for meeting large-scale production demands.

Glass Water Filling Series

This ketchup / tomato sauce filling machine is mainly suitable for filling and capping semi-liquid products without or with small particles. The tomato sauce filling machine can be customized with 4/6/8/12/14/etc filling heads according to customer’s production capacity.

Automatic Glass Water Filling Machine

Glass Water filling machines in action!

Parts details

All spare parts are designed to be fully compatible with specific models of filling machinery, ensuring minimal downtime during replacement. We adhere to international standards such as ISO 9001 and GMP, manufacturing under strict quality control. These spare parts collectively enhance the reliability, efficiency, and precision of filling machinery, making them indispensable for maintaining optimal performance in high-demand production environments.

What equipment is included in the automatic bottle filling production line?

Sunter Machinery’s fully automatic bottle filling production line integrates advanced automation technology, primarily including: efficient ultrasonic bottle washers, precise vision positioning conveyors, high-precision metering filling machines, intelligent capping/crimping machines, high-precision labeling machines, intelligent AI vision quality inspection systems, and comprehensive post-packaging equipment. These devices work in synergy to ensure the production line’s high efficiency and stable operation.

What are the brands of equipment for the filling production line?

To ensure the equipment’s superior performance and reliability, Sunter Machinery carefully selects globally renowned brand components for its fully automatic filling production line, including: Siemens PLCs and touch screens, Japanese Mitsubishi servo motors and frequency converters, ABB main motors, Taiwan AirTAC cylinders, and Schneider low-voltage electrical appliances. The combination of these high-quality components provides a solid guarantee for the production line’s stable operation.

How much capacity can the automatic e-liquid filling machine reach? How many bottles per hour?

Sunter Machinery’s fully automatic e-liquid filling machine can be customized to meet the production needs of various bottle specifications. Here are the production capacity references for different volume ranges:

- 10-30ml: Single-head filling speed is 80-120 bottles/hour; 6-12 head filling speed is 800-2000 bottles/hour.

- 30-60ml: Single-head filling speed is 60-100 bottles/hour; 6-12 head filling speed is 600-1500 bottles/hour.

- 60-100ml: Single-head filling speed is 40-80 bottles/hour; 6-12 head filling speed is 400-1000 bottles/hour.

- We can customize the number of filling heads according to customer’s actual requirements, to achieve the customer’s required production capacity.

How to ensure the stability and reliability of the automatic filling machine?

Sunter Machinery places great emphasis on the equipment’s stability and reliability. To this end, we have taken the following measures:

- Strictly implement a regular maintenance and servicing system, including cleaning equipment components, regularly checking the lubrication system, and comprehensively inspecting the entire machine.

- According to changes in market demand, timely make adaptive adjustments to the equipment, ensuring it is always in optimal working condition.

- Through regular data monitoring and analysis, timely identify and resolve potential problems, ensuring the production line’s continuous and stable operation.

What are the intelligent devices in the automatic filling machine?

Sunter Machinery’s fully automatic filling machine integrates multiple intelligent functions and equipment, including: automatic cleaning function, high-precision metering systems, high-speed filling technology, sensitive sensor and control systems, and advanced automatic inspection systems. These intelligent designs not only improve production efficiency but also ensure the stability of product quality.

Ready to Boost Your Productivity?

Contact us today to discuss your specific filling line requirements and discover how Sunter Machinery can help optimize your production process.

Contact Form

Fill out the form below and we will get back to you shortly.